Some Known Incorrect Statements About Plastic Extrusion Companies

Wiki Article

The Definitive Guide to Extruded Plastic Profiles

Table of ContentsPlastic Extrusion Companies Things To Know Before You BuyWhat Does Plastic Extrusion Manufacturers Do?Plastic Extrusion Companies for BeginnersNot known Facts About Custom Plastic ExtrusionsExcitement About Plastic Extrusion Manufacturers

We can likewise give custom-made laminations as well as would enjoy to send you samples upon request. We presently have 7 lamination stations that can manage several sorts of customized plastic extrusions. We provide custom product packaging as well as are currently packaging an extruded profile item that is marketed to a "Huge Box" Company.Be it straightforward, intricate, hollow, coextruded, or embossed, our group of professionals can tailor it for you. Furthermore, our professionals recognize that no two tasks are the very same as well as we prepare to maintain it by doing this. This implies that below at Keller Products we can offer you any type of number of items for your design needs.

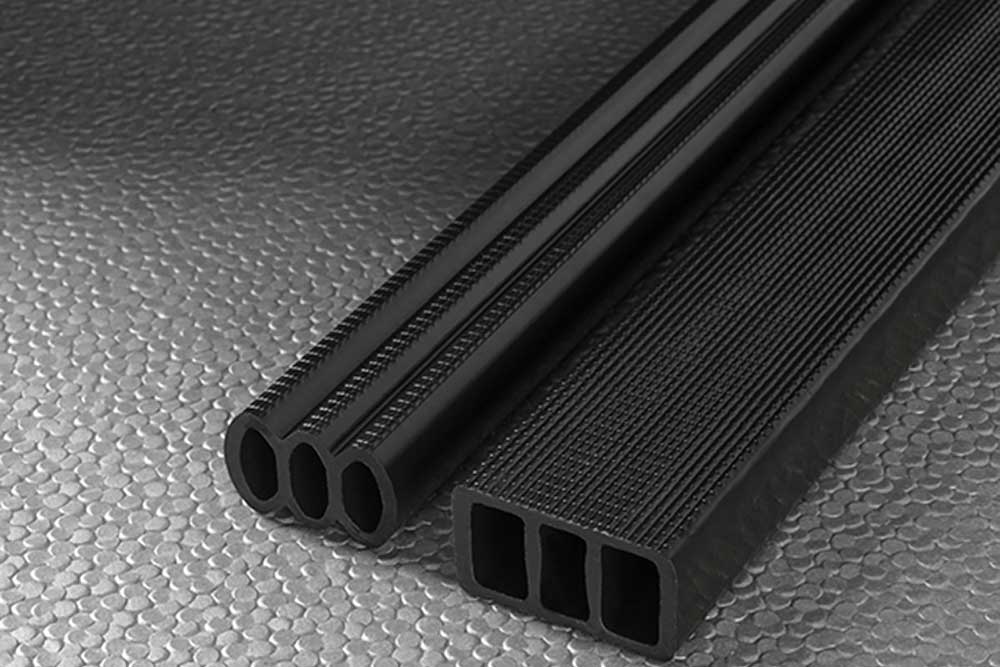

Custom extrusions are custom-made items that are produced forcibly resources through a die or mold and mildew. This process is called extrusion. Extrusion is utilized to create objects of a fixed cross-sectional profile, such as pipelines, tubes, and also poles. The raw material, called the "extrudate", is initial softened by heating.

The form of the die or mold determines the final form of the extrudate. Extrusion can be made use of to create products from a selection of materials, including steels, plastics, as well as composites. Typical applications for this process include automobile components, electrical avenue, and also weatherstripping. It is used in a range of industries, including vehicle, building, as well as manufacturing.

The Best Strategy To Use For Custom Plastic Extrusions

There are a number of firms that deal in this kind of production. These firms can assist you to make the best product for your demands and afterwards produce it using the extrusion procedure. If you have a requirement for customized products, custom extrusion associated processing may be the best remedy. Prototyping your following essential project can be as very easy as getting in touch with Alpha Custom-made Extrusions, Inc.Additionally, Alpha Custom-made Extrusions, Inc. supplies a host of secondary capabilities to finish your complete project. Call today!.

Include hinges, seals, top layers, numerous shades as well as various other features

Some Known Factual Statements About Extruded Plastic Profiles

Our receipt of your acquisition order begins the scheduling process. What is the conventional lead time for a manufacturing order? The dynamics of personalized production usually result in fast changes to tooling, production and manufacture schedules.

Exactly how long does a custom shade suit take? It commonly takes 10 functioning days to get a color chip to you for authorization, and 10 added working days to generate the customized shade concentrate from the accepted shade chip.

What is the optimum feasible width of a profile? The extrudable account is computed by measuring its established width.

The Best Strategy To Use For Plastic Extruded Profiles

We've been doing it right because 1962 and are positive that your job will gain from our thorough experience in:. plastic extrusion manufacturers. https://www.twitch.tv/k3ll3rpl4st8/about.NCS likewise provides co-extruded products of various durometers as well as various products that are co-extruded right into the very same part. If you have questions regarding co-extrusions or any of our extruded plastic products, please get to out to our team to find out much more - extrusion of plastics.

Extruded plastic forms are produced making use of a high-volume manufacturing procedure where raw plastic resin product is melted, after that compelled via a die to form a constant profile. To develop plastic extruded forms, the resin is positioned into the barrel of an extruder then gradually melted. Warmth and also stress is then utilized to compel the molten plastic into a die.

Plastic Extrusion Profiles - Truths

With just a small modification, extrusion molding can go from generating complicated forms to plastic sheets. After plastic leaves the extruder, it remains warm and also can be further controlled. This allows manufacturers to modify the form of extruded plastic utilizing rollers, shoes, or dies to satisfy the particular requirements of numerous applications.Extruded plastics are utilized throughout commercial as well as commercial applications, with some of the most common being tubing, rods, and specialty profiles. https://www.bookmarks2u.com/author/k3ll3rpl4st8/.

At Astro Plastics, our tenure in the market and also range of top-end capacities enable us to deliver on even the most complicated consumer demand. Our team of specialists works closely with you to tackle your personalized plastic extrusion requires from idea to completion, making certain you get the right item at the correct time.

Report this wiki page